Established in 1961, Metalfusioni principally traded as an aluminium foundry, then moved on to specialise in die castings in the 1970s. By combining the latest technology and modern machinery with extensive experience and know-how, the company has evolved from a modest family business to an industrial enterprise. For over 50 years, a specialised team of experts led by Maurizio Protasoni, together with trusted partners, also manages small production lots, die castings and special zamak moulds.

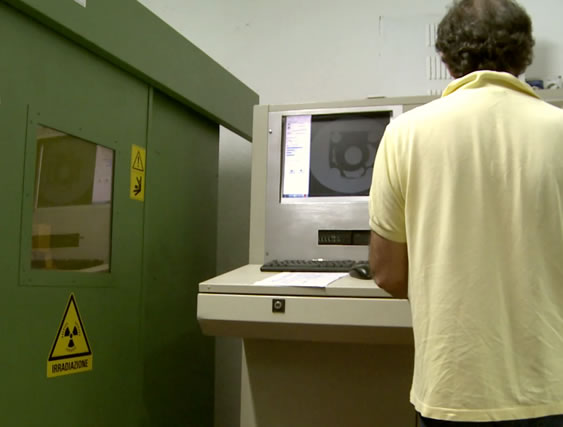

To meet our customers' needs, Metalfusioni offers an all-round service, from the development to the finishing stage, up to an accurate quality control process.